Vacuum Metallurgy

-

Izinga Lokushisa Eziphakeme Okugcwele Okuzenzakalelayo Kwe-Sintering Vacuu...

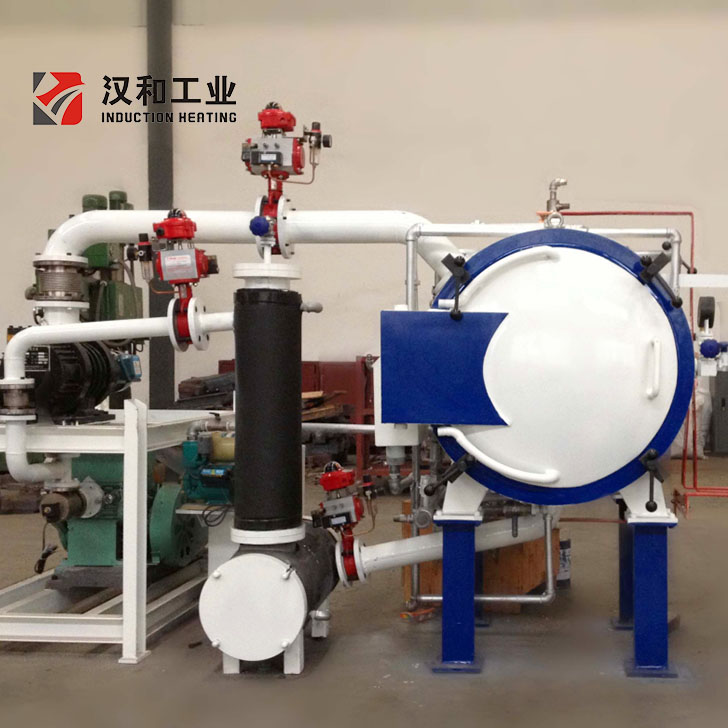

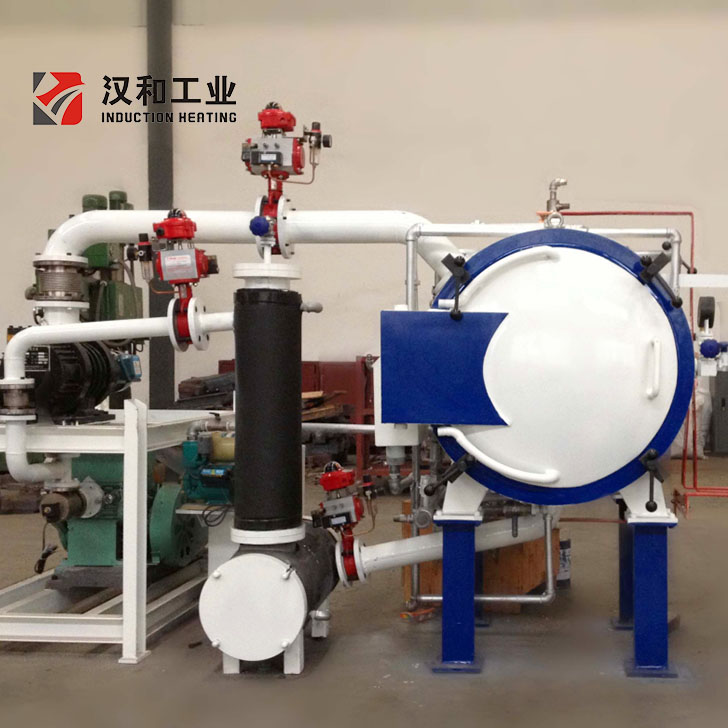

I-vacuum sintering furnace yisithando somlilo esisebenzisa ukufudumeza kwe-induction ukuze sishise izinto ezishisiwe ngokuvikela.I-vacuum induction sintering furnace iyisethi ephelele yemishini yokufaka i-carbide kanye ne-powder yensimbi ehlukahlukene ngokusebenzisa isimiso sokushisisa okuphakathi kwe-vacuum ngaphansi kwe-vacuum noma izimo zokuzivikela.Yenzelwe ukukhiqizwa kwezimboni ze-alloy eqinile, i-metal dysprosium nezinto zobumba.

-

I-High Temperature Graphite Furnace

I-graphite furnace iyisisetshenziswa sezimboni esingenza i-graphite ngamatshe ahlukahlukene namakhemikhali.Ingasetshenziselwa ukukhiqiza izinto ze-graphite ezinekhwalithi ephezulu, ukusebenza okuphezulu kanye ne-conductivity kagesi eqinile.Kunezinhlobo eziningi zesithando somlilo segraphite, uhlobo lwendiza evamile, mpo, uhlobo lokumiswa, uhlobo lwe-liquid nokunye.

-

Isithando somlilo seCrystal Single

Isithando somlilo sekristalu esisodwa sibizwa nangokuthi i-mono crystal furnace, iyithuluzi elincibilikisa izinto ze-polycrystalline ezifana ne-polysilicon ene-graphite heater endaweni yegesi engasebenzi (nitrogen ne-helium) futhi ikhulise amakristalu awodwa ngaphandle kokugudluzwa ngokusebenzisa indlela yokudonsa okuqondile.

-

I-Polysilicon Ditrctional Soldificatiion Furnace

Isithando somlilo esiqondisayo siwumshini wesimanje osebenzela ukuncibilika kwensimbi noma ingxubevange enokufudumala kwemvamisa ephakathi nendawo ngaphansi kwe-vacuum, yakhe i-gradient eshisayo ngesithando somlilo esiklanywe ngokukhethekile kanye nesistimu yokupholisa, futhi ilungiselela ukuqiniswa kanye nekristalu eyodwa ngokudonsela phansi indlela.Ingakwazi ukulawula ngokuqinile izinga lokushisa nokuqukethwe kwe-alloy yezinto.Ukuthola i-gradient ephezulu kakhulu yezinga lokushisa kanye nesixhumi esibonakalayo esiqinisayo esibushelelezi, yamukelwa ngokuqokwa okukhethekile esidingweni sayo se-gradient.Isithando somlilo sethu sokuqinisa isiqondiso siklanywe ngendlela eqondile enomsebenzi wendawo encane endaweni yokusebenzela.

-

Isithando somlilo esincibilikisayo esenziwe ngokwezifiso

I-Vacuum Induction Melting (VIM) ukuncibilika kwensimbi ngokungeniswa kwe-electromagnetic ngaphansi kwevacuum.Isithando somlilo esifakiwe esiqukethe i-refractory line crucible ezungezwe ikhoyili yokungeniswa sitholakala ngaphakathi kwegumbi le-vacuum.Isithando somlilo esingeniswayo siwumthombo wamandla oxhunywe imvamisa ehlobana ngokunembile nosayizi wesithando somlilo nezinto ezincibilikiswayo.